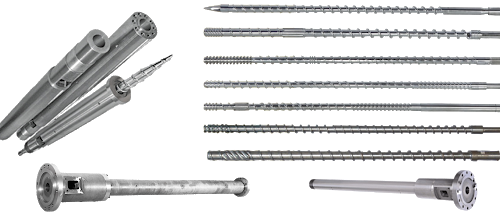

Sai Extrumech Pvt. Ltd. offers standard application finished screws through flight tipping as well as fully encapsulated screws. This combined with corporate research and development, has enabled Sai Extrumech Pvt. Ltd. to offer barrel material, screw finishes and screw geometries for nearly every extrusion machine and plastics processing application.

Screw designs within the Sai Extrumech Pvt. Ltd. have evolved over several decades from simple single flight Geometries to sophisticated barrier/mixing designs. State-of-the-art advances in screw design have improved the melting and solids conveying capabilities of the single screw extruder, leading to higher productivity. The most significant advances in melting are being realized due to our patented barrier screw geometries Sai Extrumech Pvt. Ltd. can supply almost any size of extrusion screw for almost any application, and also offer a comprehensive rebuilding service too.

Just remember the most important element in any extrusion system is the feeds crew and is responsible for the critical functions of feeding, solid conveying, melting, mixing and pumping.

Feeds Crew Technology

Our ability to design and manufacture some of the industry’s most advanced and efficient feedscrews is one reason we have been an extrusion leader for more than 10 years. With our R&D facilities and team of experienced polymer process engineers, we offer customers world class screw design and technical capabilities.

R&D Capabilities

- Our primary research and development center in Pawcatuck, Connecticut, USA, enables us to research, test, and supply custom feeds crew designs.

Quality Materials

- Feeds crews manufactured from a variety of metals for corrosion and wear resistance.

Screws for Every Application

- Screw sizes range from ½ inch (13mm) to 12 inches (300mm) for single screw, and 40mm to 140mm for counter-rotating twin screw. Screws, including smooth and groove feed designs, can be customized for specific applications.

Proven Technology

- Barrier screw technologies are known worldwide for consistently higher output rates, process stability, venting and devolatilization capabilities, distributive and dispersive mixing properties, and minimized polymer degradation.

Process Technology

- Our experienced team of process engineers work with our customers on unique features.

Barrels

Our primary manufacturing facility is in the single screw production, service, and support. We build one piece barrels ranging in bore size from 1 to 20 inches (25 to 500mm) in diameter and up to 185 inches (4,700mm) long. Two piece barrels are available in lengths ranging from 185 to 295 inches (4,700 to 7,500mm).

Quality

- Our alloys provide dramatically enhanced abrasion and corrosion resistance to barrels operating under severe conditions, especially those using filled materials including glass, titanium, dioxide, quartz, talc, mineral oxides and others.

Selection

- We can manufacture virtually any barrel including vented, groove-feed, nitride, jacketed, and re-sleeved.

Durability

- New barrels for plastics and rubber applications are designed to last four to five times longer than equivalent nitrided products.

Quick Turn

- Around With knowledge of virtually every extruder brand in operation today, we have the expertise, people, and production facilities to supply you with barrels anywhere in the world.

Barrel Alignment

The purchase of a new barrel or screw can often be a considerable expenditure for an organization, not perhaps in the initial purchase price of the replacement part but in the time, planning and lost production in making the change.

It is essential that companies therefore protect that investment and ensure that their new components are installed in the appropriate manner. The alignment of the barrel, feed housing and gearbox drive shaft are critical in the installation to avoid premature wearing of the components and subsequent loss in production rates in the future.

Sai Extrumech Pvt. Ltd. understands these issues and offers a laser alignment service to ensure that these components are in their optimum condition before production restarts.

Our visiting engineer will measure the initial deflection and then assist your production staff in making the simple adjustments until the positioning of the components are as near to nominal as possible, thus protecting your investment for the future.

Inspection & Measuring

Screws and barrels used in plastics/rubber processing naturally wear over time and companies often don’t realize the consequences that this wear process can have on the quality and quantity of production from their machinery.

Sai Extrumech Pvt. Ltd. understands implicitly these issues and offers an Inspection and Measuring Service to help customers determine how to maintain their machinery in peak condition.

Our visiting engineer will inspect both barrel and screw conditions and submit to the client a written report on the condition of the components and the recommended remedial action required if any.

Again, Sai Extrumech Pvt. Ltd. will work with you to protect your production equipment from the consequences of worn and/or deteriorating components.

Fill Out the Form Bellow For Inquiry