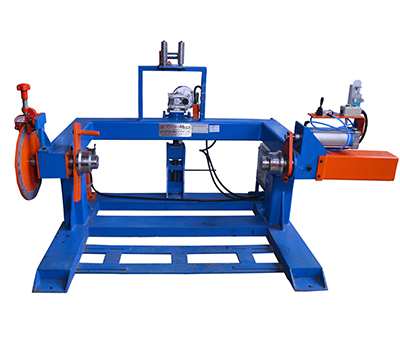

This traversing type unit allows keeping the cable straight at all times during the haul off process.

Bobbin load/unload, locking/unlocking, and traversing operations are fully motorized.

When using dual pay off/take up, the front stand can be moved aside from the machine’s centerline, allowing to use the rear stand thus getting a continuous run.

The machine is provided with an MMI+PLC control system for pre-setting traversing pitch and for drum speed control.

When using a large cable, the pay off can be equipped with a speed detecting dancer for speed synchronization.

The pay off system is a necessity for continuous production. Two housings made of mild steel iron are so placed that the outlet of the wire comes in the centre. The inner end of the wire and the starting end of the full reel is led out of a horizontal slot of the housing and welded together, thus ensuring a continuous run.

Each housing is equipped with a reel lifting carriage containing the mandrel for the reels, the flyer disk and the AC motor. The wire is paid off via the flange of the non-rotating reel which is lifted on the spindle driven by a reversible three-phase AC motor. The motor is fed via a plug-in cable from the control board.

- Reel lifting by electro lifting spindle.

- Activation by switch

- A flexible connection allows a traveling path of 2.5m

- Each reel carriage is equipped with a braked wheel, which allows blocking the trolley.

Travel drive for reel carriages movable by an AC motor.

At the Pay off housing a wire change detection is mounted. The device gives a signal if a reel change is necessary to have continuous production.

Dual Take-up

| The Automatic Dual Take up is a robust structure enabling the continuous production of wire without stopping for change over of bobbin. The complete structure is guarded for operator protection. The complete system is Pintle type and the bobbin loading & unloading system is taken care of by sensor actuatedcarriage system which is motor-driven. The locking & unlocking of bobbin is also actuated by sensors.

The smooth automatic changeover of wire winding from one bobbin to another bobbin ensures that no time is wasted in changing the loaded bobbin and placing the empty bobbin. |

The accurate catcher system along with effective cutter provides Customer unmatched ease of operation at all speed and for all wire range.

The system is driven by high torque AC frequency motors that take care of a wide range of torque required to run different wires product mix. The smooth braking system ensures that wire tension does not get disturbed while stopping the driven bobbin.

The precision traversing system ensures the perfect winding of wire on the bobbin of any pitch. The entire system is actuated and protected through sensors at every stage.

| Type | : | Pintle type |

| Size of bobbin | : | 630mm |

| Max. Width | : | 475mm |

| Barrel dia | : | 350mm |

| Max. Speed | : | 600 Meter/Min |

| Max. Size of Cable | : | 6mm Dia |

| Loading/Unloading | : | Automatic |

| Bobbin holding | : | Pintle |

| Change over | : | Automatic |

| Cutting of wire | : | Automatic |

| Drive | : | 2NO 8 KW AC Frequency Variable |

| TRAVERSE | : | Adjustable Driven by 1.1KW AC Frequency variable Drive. |

Fill Out the Form Bellow For Inquiry