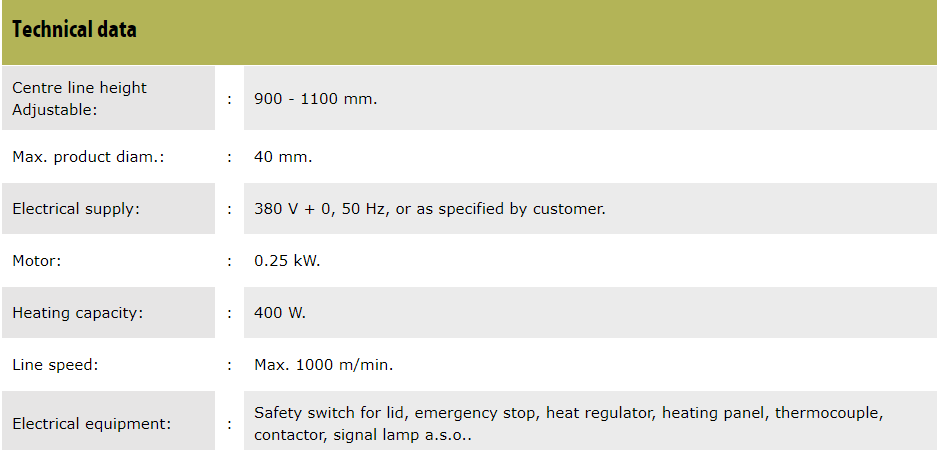

The Sai Extrumech Pvt. Ltd. Powder on the product and the size of the product. The brushes are smoothening the through passing product and are taking away the surplus of the powder material which is continuously fed back into the powder storage chamber by means of a step less speed adjustable rotating screw (AC-Drive converter). The brush set rotation speed is driven by a chain transmission from the screw Applicator is design to apply powder e.g. Chalk, Talc, Calcium Stearate or Graphite on cables, profiles or hoses. The application of powder on the through passing product is done by means of a rotating bridge preventer spring as well as by an adjustable set of 3 counter rotating brushes. The brush set is adjusted according to the needed amount of powder. There is an inspection hole above the brush set in order to supervise the brushes during operation so that the rotation speed of the screw/brush set can be adjusted accordingly. Also available is a provision on the outlet side after the brushes to connect a vacuum suction device to remove even more powder from the product if necessary. Refill of powder is done during continuous operation by pouring powder into a funnel directly over the powder chamber. The powder chamber is electrically heated, preventing the powder from clogging and absorbing humidity. The complete unit is movable on wheels, adjustable to line height and can be used for continuous application of powder to cables, hoses, profiles a.s.o.. All parts in direct contact with powder are made out of stainless steel. The operator panel is easy reachable above the machine and can be swiveled around to adjust to the line direction. The Powder Applicator acc. to draw. no. 3-300041-02 corresponds to the new European regulations and is delivered with the CE-label and a conformity certificate.

Fill Out the Form Bellow For Inquiry