Comprehensive Screw and Barrel Assembly Solutions

Introduction

At Sai Extrumech, we provide complete screw and barrel assemblies designed for precision and durability. Our components cater to the rigorous demands of plastic processing machinery, ensuring seamless performance, reduced downtime, and extended operational lifespan.

Features:

• High Efficiency.

• Robust Construction.

• Resistant to wear and tear.

• High-strength steel alloys.

• Precise tempreture control.

• Moduler Design.

By leveraging our cutting-edge designs, manufacturers can unlock significant productivity gains, reducing cycle times and achieving enhanced overall efficiency.Additionally, our solutions facilitate precise control over the extrusion process, resulting in superior product quality, exceptional color uniformity, and reduced material waste.This synergy of speed, consistency, and quality empowers businesses to stay ahead in competitive markets, drive innovation, and achieve sustainable gwowth.

Screw Barrel Assembly Parts

Our assemblies include high-quality components, such as:

- Bimetallic Screws: Enhanced durability for challenging applications.

- Nozzles: Precision-engineered for superior extrusion and injection performance.

Injection Molding Machinery Parts: Built to optimize plastic machinery output.

Screw Rebuild/Repair

- Repair the internal thread.

- Repair the shank (drive section).

- Repair the removable nose.

- Rebuild the top of the flight with hard facing.

Barrel Repair

- Re-sleeve the stroke section or full length of the barrel.

- Honing of the stock area.

- Grinding, Honing and Nitriding of old barrel with new size screw.

- Pressure testing and acid flusing for rubber processiong barrels.

- Press-out broken screw from barrel.

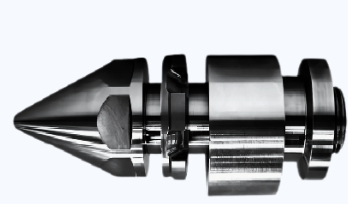

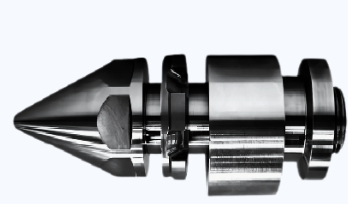

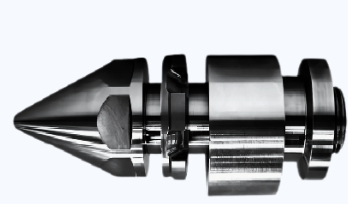

Screw Tips for Injection & Extruder Machines

We manufacture screw tips that meet stringent industry standards, ensuring high-quality results:

- Depth of Nitrated Layer: 0.5–0.6mm.

- Nitration Hardness: 66–68 HRC, with fragility below Grade 1.

- Surface Roughness: Ra 0.4µm for smooth operations.

- Cr-Coating Hardness: ≥950 Hv with a layer thickness of 0.03–0.08mm.

- Bimetallic Layer: Hardness of HRC55–72 and a depth exceeding 2mm for robust performance.

Key Screw Assembly Parts

Our range of screw assembly components includes:

- Plastic Machine Parts: Crafted for reliability and precision.

- Distributor & Collar: Essential for maintaining material flow.

- Screw Cap & NRV Sets: Ensuring consistent and efficient operation.

Components of Barrel Assembly

We offer complete barrel assembly components that deliver high performance and longevity:

- End Cap: Secures the barrel assembly for optimal operation.

- Flange & Adaptor: Precision parts ensuring structural stability.

- Cooling Ring: Regulates temperature to prevent overheating.

- Head Nozzle for Molding Barrels: Engineered for accurate material discharge.

Repairing Solutions for Screw & Barrels

Screw barrel assembly parts include components like bimetallic screws, nozzles, and injection molding machinery parts for plastic machinery.

Screw assembly parts:

Plastic machine parts, Distributor, Collar, Screw Cap & NRV Sets.

Screw Tips for Injection & Extruder Machine

1. Depth of Nitrated Layer: 0.5-0.6mm.

2. Hardness of nitration: 66-68 HRC.

3. Fragility of nitration: Less than grade 1.

4. Surface roughness: Ra 0.4um.

5. Hardness of Cr-coating Layer: > 950Hv.

6. Thickness of Cr-coated Layer: 0.03- 0.08mm.

7. Hardness of Bimetallic Layer: HRC55-72 8. Depth of Bimetallic Layer: >2mm

Barrel assembly parts:

End cap, Flange, Adaptor, Cooling Ring, Head & Nozzle for Moulding Barrels.

FAQS

Screws and barrels are critical components in extrusion processes. They work together to melt, mix, and convey raw materials through the extruder to create the desired product shape.

Screws and barrels are typically made from high-quality, wear-resistant materials such as nitrided or bimetallic alloys. These materials ensure durability and long service life, even under demanding processing conditions.

Yes, we offer customized solutions tailored to meet your specific needs. Whether it’s a unique design, material choice, or specific dimensions, our team can create screws and barrels that enhance your production process.

Selecting the right screw and barrel depends on factors such as the type of material being processed, the desired product characteristics, and the specific requirements of your production process. Our experts at Sai Extrumech can help you choose the best components for optimal performance.