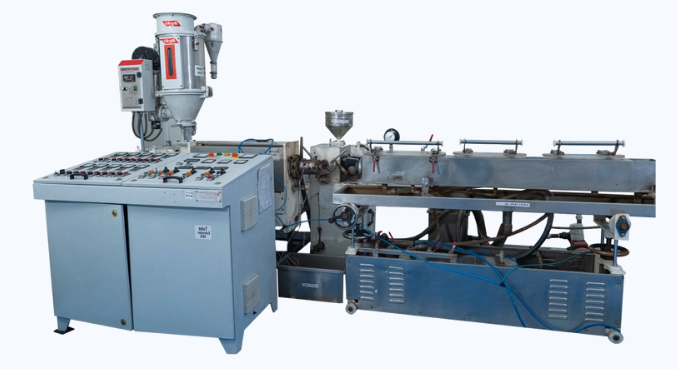

PU Pneumatic Tubing Extrusion Line

Introduction

This extrusion line is designed for producing polyurethane (PU) tubing used in pneumatic applications requiring flexibility and durability.

Application:

- Pneumatic systems in industrial automation.

- Compressed air delivery.

- Tubing for robotics and machine tools.

Features:

- Precise control over tubing diameter and wall thickness.

- Abrasion and kink resistance for durability.

- High-speed production capabilities.

- Customizable colors and sizes for various industrial needs.

Typical Composition:

- PU resin as the base material.

- Extruder with temperature and speed optimization.

- Calibration and cutting units for uniform tube dimensions.

FAQS

What is an extrusion line for pipe and tube?

An extrusion line for pipe and tube is a manufacturing system designed to produce high-quality pipes and tubes from various materials. The system melts and shapes raw materials into the desired pipe or tube form through an extruder and die.

What are the key components of an extrusion line for wire and cable?

The key components of an extrusion line include:

- Extruder

- Cooling Trough

- Take-Up and payoff.

- Control System

- Capstan

Can Sai Extrumech customize extrusion lines for specific requirements?

Yes, Sai Extrumech offers customized extrusion lines tailored to meet specific customer requirements. We work closely with our clients to understand their needs and design solutions that optimize performance and efficiency.

What are the benefits of using Sai Extrumech's extrusion lines for wire and cable?

Benefits include:

- High precision and efficiency.

- Affordable units with excellent quality

- Customizable solutions to meet specific needs.

- Expert technical support and service.