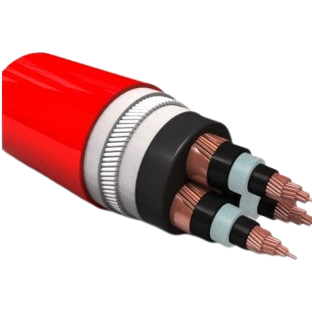

Power Cable

Introduction

Power cable extrusion lines manufacture cables for high-voltage and low-voltage power transmission.

Application:

- Power grids and distribution networks.

- Renewable energy systems (solar, wind).

Features:

- Ability to handle high voltage with minimal loss.

- Shielding for electromagnetic interference.

- Fire-resistant insulation for safety.

Typical Composition:

- Copper or aluminum conductor.

- XLPE or EPR insulation.

- Metallic shielding and outer jacket.

FAQS

What is an extrusion line for wire and cable?

An extrusion line for wire and cable is a manufacturing system designed to produce high-quality wire and cable products. It typically involves feeding raw materials into an extruder, which melts and shapes them into the desired wire or cable form through a die.

What types of wire can be made in SAI’s extrusion line?

- Extr line – Building wire

- Industrial cable

- Submersible cable

- Power cable

- Optical fibre cable

- THN/LAN Cable

- Solar cable

- Sioplas cable

- Tandum cable

What are the key components of an extrusion line for wire and cable?

The key components of an extrusion line include:

- Extruder

- Cooling Trough

- Take-Up and payoff.

- Control System

- Capstan

Can Sai Extrumech customize extrusion lines for specific requirements?

Yes, Sai Extrumech offers customized extrusion lines tailored to meet specific customer requirements. We work closely with our clients to understand their needs and design solutions that optimize performance and efficiency.

What are the benefits of using Sai Extrumech's extrusion lines for wire and cable?

Benefits include:

- High precision and efficiency.

- Affordable units with excellent quality

- Customizable solutions to meet specific needs.

- Expert technical support and service.

Our Partners