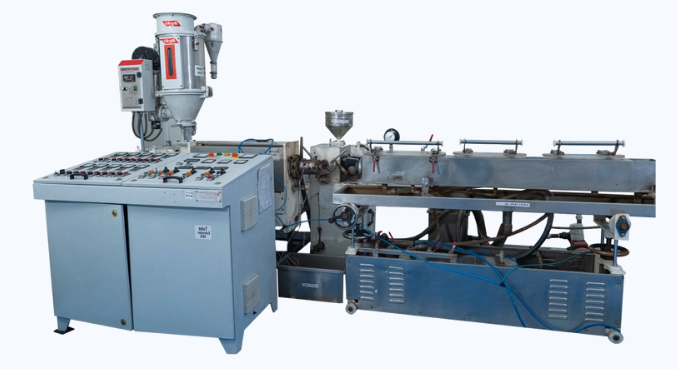

Medical Tubing Extrusion Line

Introduction

This extrusion line is specialized for producing precision medical tubes used in healthcare and medical equipment. It ensures strict compliance with industry standards for hygiene, safety, and material properties.

Application:

- Catheters and IV tubing.

- Tubes for oxygen delivery systems.

- Fluid drainage and feeding tubes.

Features:

- High precision extrusion for tight tolerances.

- Material compatibility with biocompatible plastics like PVC, silicone, and TPU.

- Inline quality inspection systems (e.g., laser measurement).

- Cleanroom compatibility for medical-grade production.

Typical Composition:

- Extruder with medical-grade polymer handling.

- Calibration and cooling tanks for dimensional accuracy.

- Take-off and cutting systems for exact tube lengths.

FAQS

An extrusion line for pipe and tube is a manufacturing system designed to produce high-quality pipes and tubes from various materials. The system melts and shapes raw materials into the desired pipe or tube form through an extruder and die.

The key components of an extrusion line include:

- Extruder

- Cooling Trough

- Take-Up and payoff.

- Control System

- Capstan

Yes, Sai Extrumech offers customized extrusion lines tailored to meet specific customer requirements. We work closely with our clients to understand their needs and design solutions that optimize performance and efficiency.

Benefits include:

- High precision and efficiency.

- Affordable units with excellent quality

- Customizable solutions to meet specific needs.

- Expert technical support and service.